Worldwide Pipe Meets Industry Standards

Worldwide Pipe Meets Industry Standards

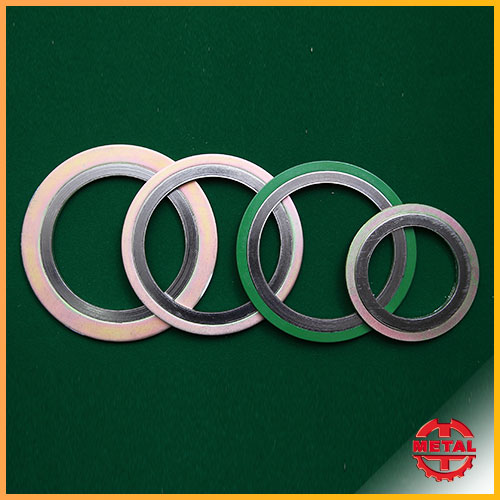

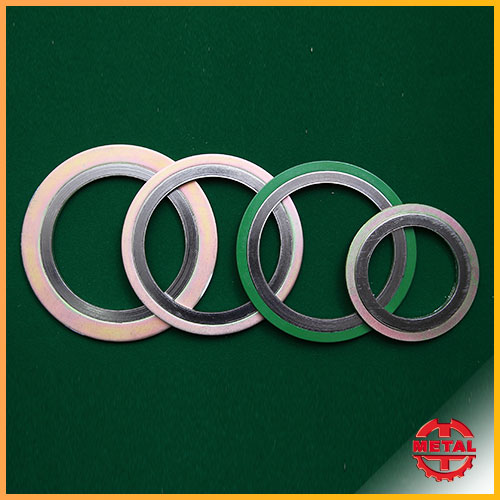

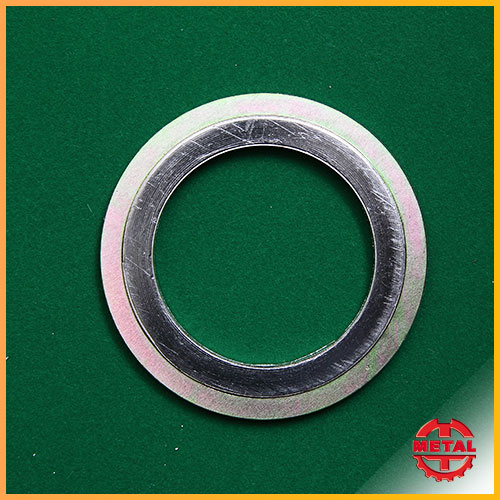

Seal purpose for flange, valve and etc.

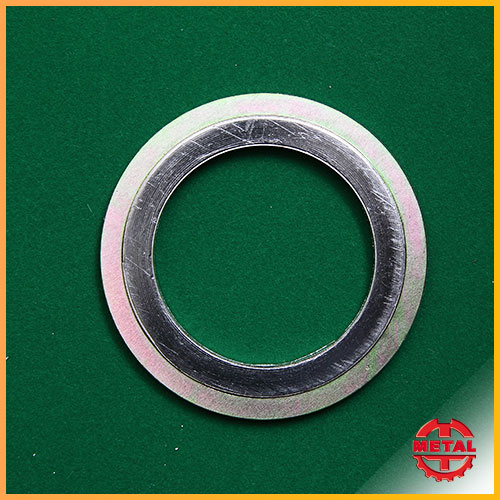

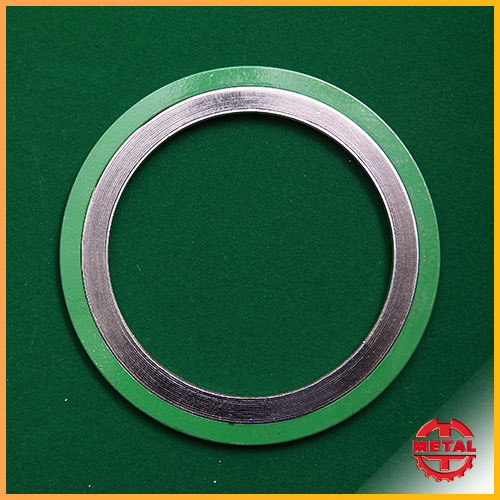

The metal gasket is designed to withstand extreme temperatures, pressures and chemical corrosion. These sturdy metal gaskets are available in standard and customized configurations, and are made of a variety of materials, which can be adapted to all types of process applications.

From the size of the gasket to its ability to withstand degradation and damage, everything plays a role in its ability to prevent air, gas, water or other fluids from escaping. The gasket is placed between two flushing surfaces, which have channels for fluid movement. Since the two surfaces may not be perfectly flush or straight, there will be gaps between them through which fluid can pass. The gasket corrects these gaps by compressing the gaps between the two surfaces to effectively eliminate any leakage paths.

The main selection factors of gaskets-gasket material, type and purpose.

Some factors that buyers should consider when purchasing Metal Gasket include:

The force that the two surfaces will emit on the gasket

Surface unevenness (determines the thickness of the gasket)

Liquids and any environmental pollutants

Compressibility of gasket material

If you know all the details of the application environment, you can choose gasket materials that can withstand the influence of water, acidic or alkaline chemicals, oxidation and more factors. You can also choose gaskets with suitable thickness, service life and ductility.

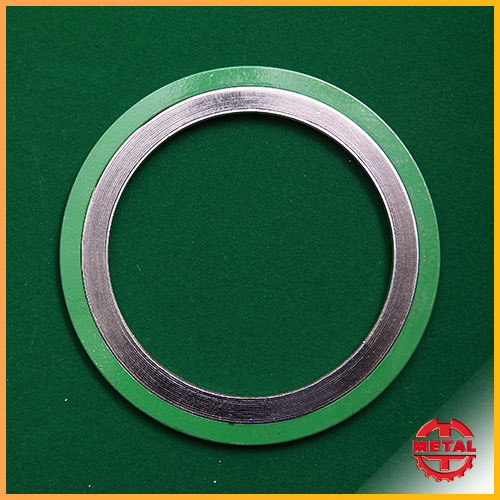

Seal purpose for flange, valve and etc.

The metal gasket is designed to withstand extreme temperatures, pressures and chemical corrosion. These sturdy metal gaskets are available in standard and customized configurations, and are made of a variety of materials, which can be adapted to all types of process applications.

From the size of the gasket to its ability to withstand degradation and damage, everything plays a role in its ability to prevent air, gas, water or other fluids from escaping. The gasket is placed between two flushing surfaces, which have channels for fluid movement. Since the two surfaces may not be perfectly flush or straight, there will be gaps between them through which fluid can pass. The gasket corrects these gaps by compressing the gaps between the two surfaces to effectively eliminate any leakage paths.

The main selection factors of gaskets-gasket material, type and purpose.

Some factors that buyers should consider when purchasing Metal Gasket include:

The force that the two surfaces will emit on the gasket

Surface unevenness (determines the thickness of the gasket)

Liquids and any environmental pollutants

Compressibility of gasket material

If you know all the details of the application environment, you can choose gasket materials that can withstand the influence of water, acidic or alkaline chemicals, oxidation and more factors. You can also choose gaskets with suitable thickness, service life and ductility.