Worldwide Pipe Meets Industry Standards

Worldwide Pipe Meets Industry Standards

Views: 0 Author: Site Editor Publish Time: 2025-09-01 Origin: Site

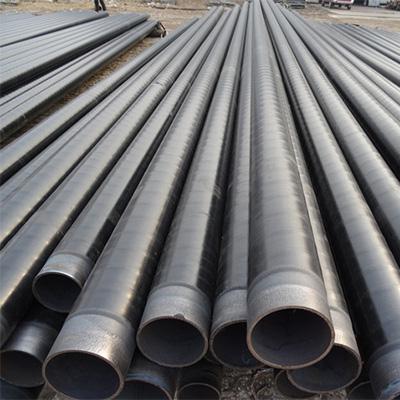

In the transportation of oil and gas, urban water supply and drainage, and the construction of long-distance pipeline networks, achieving a balance between high-strength pressure resistance and long-term corrosion protection is crucial for determining the total lifecycle cost. 3LPE Coated Seamless Steel Pipes deeply integrate the 'dense strength of seamless steel pipes' with the 'three-layer PE external corrosion protection system,' continuously providing reliable protective performance.

Ⅰ. Synergistic Advantages Of Seamless Steel Pipe Substrate

Seamless steel pipe structures are uniform and highly dense, suitable for high pressure, pulsating pressure, and complex temperature differential cycles. After being coated with 3LPE, pitting/crack corrosion can be significantly slowed down; the outer PE layer also provides secondary cushioning for FBE, reducing the risk of scratches during transportation and installation. For long-distance pipelines, the 3LPE system helps maintain stable electrical insulation performance of the pipeline.

Ⅱ. Typical application scenarios of 3LPE Coated Seamless Steel Pipes

1) Oil and gas long-distance transmission: Suitable for transporting crude oil, refined oil, and natural gas, while also considering chemical resistance and construction strength.

2) Urban gas and industrial medium pipelines: Reduce corrosion rates in moist soil, salt fog, and contaminated soil, extending maintenance cycles.

3) Coastal/high groundwater level areas: Maintain low water vapor permeability and good weather resistance in high humidity and high salinity environments.

Ⅲ. 3LPE Coated Seamless Steel Pipes Selection and Parameter Recommendations

1) Steel pipe substrate: Often paired with seamless pipe systems such as API 5L, ASTM A106/A53, etc., selecting grades based on pressure ratings and media.

2) Coating structure: Prefer high adhesion FBE primer and performance-stable copolymer adhesive; outer protective layer PE thickness is configured according to diameter and burial depth grades, balancing mechanical protection and cost control.

3) Length and processing: Available in lengths of 5.6m, 5.8m, 6m, 11.6m, 12m, and random lengths as specified, with support for threading, beveling, fittings, and on-site joint systems.

Ⅳ.Why choose METAL's 3LPE Coated Seamless Steel Pipe?

Metal company can provide an integrated supply from scheme selection, custom length and end processing, to 3LPE anti-corrosion and on-site jointing systems; relying on a stable material chain and strict quality control, it helps customers achieve the optimal balance between 'high-pressure resistance×long-lasting corrosion protection × constructability', significantly reducing maintenance frequency and shutdown risks.

For technical specifications, sample pipes, or on-site technical support, please contact Mait's engineering team for customized solutions and quotations.

How to Identify High-Quality Seamless Steel Pipes?Surface & Dimension Guide

High-Pressure Seamless Steel Pipe for Oil & Gas Pipeline Systems

30 Years of Quality: How Hebei Metal Builds Reliable Seamless Steel Pipe Supply

What Are the Two Main Methods Used to Produce Seamless Steel Pipes?

Stainless Steel Welded Pipe vs Seamless Pipe | Strength & Applications

High-Strength Black Painted Seamless Steel Pipes: Features and Applications

3LPE Coated Seamless Steel Pipe: The Ideal Durable Anti-corrosion Solution

Hot-Dip Galvanized Seamless Steel Pipes: Strong, Reliable, and Built to Last

From Pickling to Packaging: Exploring the Seamless Pipe Galvanizing Process